CNC LASER PROCESSING MACHINEIGNIS EF800

The IGNIS EF800 is designed for perform deep 3D engraving applications on an extended work area. The galvo head provides machining with a working field of 120mm x 120mm*. To increase the standard working field of the galvo head, it was placed on a CNC kinematic system, as a result, the machining field was increased to dimensions: 600mm x 400mm X 300mm* (XxYxZ) without compromising the accuracy of the engraving. For example, this provides the ability to machine several nests injection mold or machining a larger nest than the working area of the working area of the electroplating head alone.

*depending on the optical system

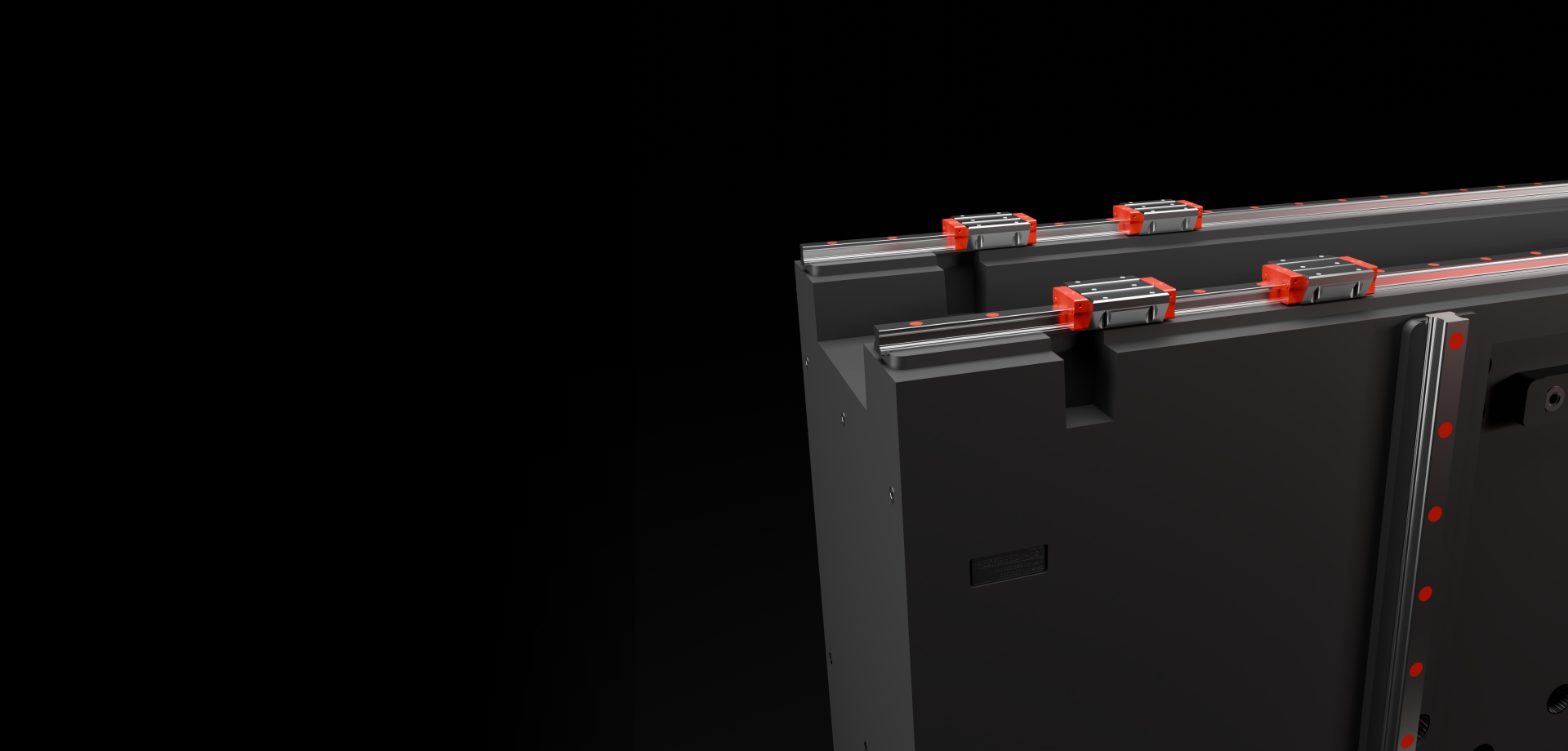

Mineral-Casting BasePrecision and vibration damping capability

- High vibration damping capability: Mineral castings provide up to 10 times better vibration damping capacity than gray cast iron, which is essential for reducing vibration and improving machine accuracy.

- High precision: polymer concrete bodies for the IGNIS EF800 machine feature superior machining accuracy.

- High rigidity and stability: mineral casting is a very rigid material that can withstand heavy loads and stresses without deforming.

- Environmentally friendly: Mineral casting is a green material made from recyclable materials. When casting, heating metal melting furnaces, which consume huge amounts of energy, is not required.

DIE PRODUCTION

The IGNIS EF800 is ideal for use in industries where dies, punches and molds are made.

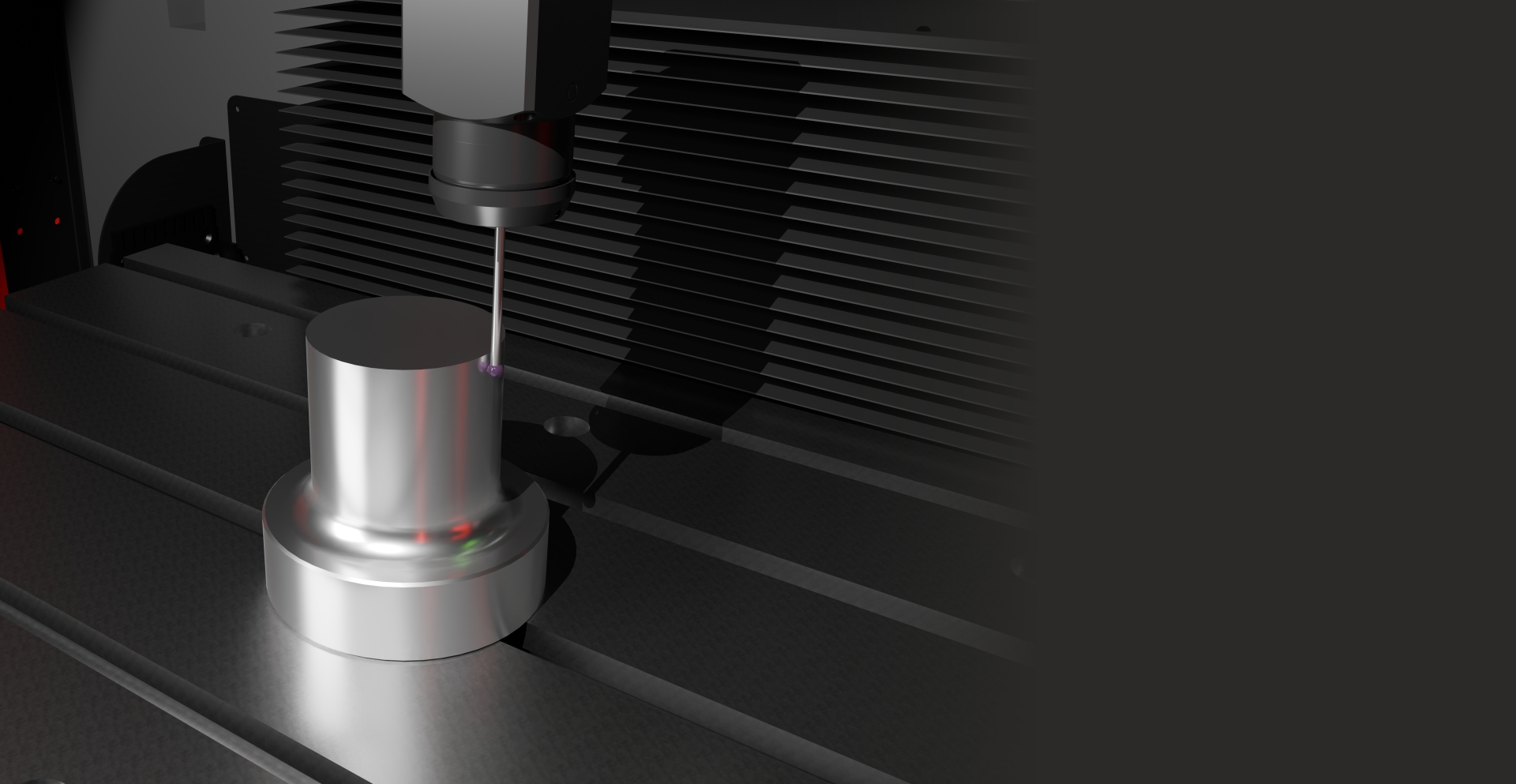

POSITIONING OF WORKPIECES

The IGNIS EF800 can be equipped with a vision system for finding the position and orientation of flat parts as well as a touch probe supported by full CNC cycles in IGNISoft software.

IGNISoft 3D SoftwareProprietary IGNISoft 3D software allows 3D file processing (STL, OBJ formats) and machine control to produce 3D structures. The machine combined with the software is a standalone product and does not require auxiliary, external software for 3D path programming. Simply import the model and let the software do its thing. The software offers basic manipulation of 3D objects - axial reflection or positioning. Open database of processing parameters allows quick processing with unrestricted modifications of existing parameters.

- Quick 3D object processing and modifications (STL, OBJ)

- Path optimization

- Marking function (dxf, dwg files)

- Variable text marking (from text file or serial numbers)

- Transforming 2D objects into 3D objects

- Parameter library

- Multiple languages (available languages: Polish, English)

- E-mail notification after processing

INTUITIVE SOFTWARETO MATCH YOUR NEEDS